By Kimondo Maina, DevReporter, Nyeri County

Key Highlights

- Khaki packaging is helping address Kenya’s unemployment challenge.

- The khaki packaging business empowers persons with disabilities (PWDs), ex-prisoners, and residents of recovery centres by equipping them with essential skills.

- Waste materials are repurposed into charcoal briquettes, promoting environmental conservation and zero-wastage.

Despite their talents, academic qualifications, and determination, many young Kenyans struggle to find jobs.

A recent Statista report indicates that the unemployment rate in Kenya is 6.61%. The National Council for Population and Development reports that 67% of those unemployed are youths.

For many, job hunting in Kenya is a grueling and exhausting process—a relentless battle against an unyielding tide that rarely favours job seekers.

“Finding a job is very difficult. People always walk around here with papers and documents looking for jobs,” lamented Irene, a young Kenyan.

Glimmer of Hope

Amidst the challenges of unemployment, there is a glimmer of hope in the form of khaki packaging bags.

In Witeithie, Juja, entrepreneur Charles has established a business focused on manufacturing khaki paper products by hand. This initiative follows Kenya’s 2017 ban on manufacturing and use of polythene bags, a move taken to address environmental concerns associated with plastic waste.

While a student at the Jomo Kenyatta University of Agriculture and Technology (JKUAT), Charles sought to contribute to the solution.

“I conducted research to understand why the government banned plastic bags, aiming to find an alternative,” he explained.

Historical Insight

Through his research, Charles discovered that khaki packaging was commonly used in the 1970s and 1980s. Inspired by this historical insight, he delved deeper, sourced the necessary raw materials, and launched his venture, Jamii Ltd.

This initiative has not only created significant employment opportunities, it also provides training for a diverse range of individuals, including women, youth, PWDs, and ex-convicts. Participants gain vital skills and a stable income by producing various products tailored to market needs.

“We offer packaging bags, envelopes, book covers, popcorn bags, cake boxes, and gift bags,” said Mary, a trainer at Jamii Ltd.

Social Impact

Beyond training and job creation, Jamii Ltd is dedicated to making a broader social impact.

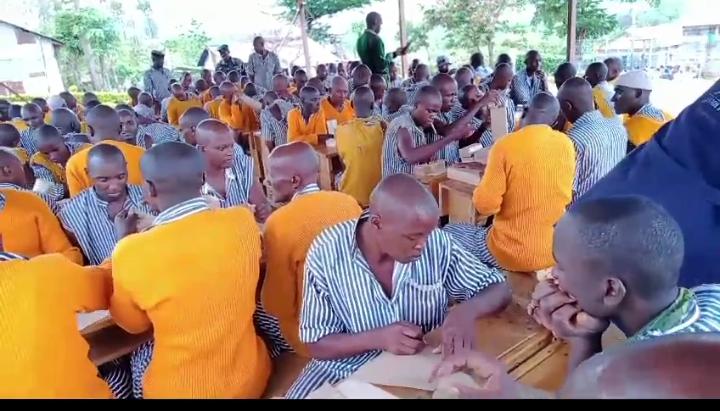

Through this initiative, marginalised groups, such as Persons With Disabilities (PWDs), their caregivers, ex-convicts, and individuals in recovery, gain hands-on skills.

Jamii Ltd has facilitated training programmes through partnerships that equip these individuals with valuable skills.

Success Story

Rose, who was incarcerated at Lang’ata Women’s Prison for 11 years, is a success story of these partnerships.

While serving her sentence, she benefited from a training session conducted by Charles at the facility last year.

Now, having been out of prison for one month, Rose is optimistic about her reintegration into society.

“I learned this at Lang’ata Prison last year. There is a lot of training there, but I saw this as a great opportunity, especially since I will be taking it back to Homabay. I plan to uplift women, persons with disabilities, and widows because it is something people can do.

“I have decided to advocate for women’s empowerment nationwide. Whenever I am called, I will go to empower those with disabilities and other ex-prisoners reintegrating into society who have nothing to do,” Rose said.

Environmental Sustainability

In addition to creating jobs and supporting social causes, Jamii Ltd is dedicated to environmental sustainability.

The company employs a zero-waste approach by repurposing production waste and used packaging bags into charcoal briquettes. This innovative practice minimises waste while providing a sustainable energy source.

“We recycle our waste to produce charcoal briquettes. Everything we provide is eco-friendly, and we take our commitment a step further by recycling the waste we generate. We adhere to zero-waste approach,” Charles explained.

As Kenya joins Rwanda in becoming a benchmark for Eastern African countries by banning plastic bags, Charles’ venture aligns with Kenya Vision 2030.

The aim is to eliminate unnecessary and problematic single-use plastic packaging through redesign and reuse delivery models, promoting the sustainable development goal of responsible production and consumption.